PerfoTec

PerfoTec wants to prevent the waste of vegetables, fruit and flowers is a progressive technology company that provides innovative and sustainable packaging solutions for flowers, vegetables and fruit.

PerfoTec laser and O2-Control

This video shows how the PerfoTec laser and O2-Control are connected to an existing packaging line at a customer in the US.

With the equipment and the information from the respiration meter, we, together with this customer, were able to more than double the shelf life of their salad product!

The respiration meter automatically translates the information about the respiration of the salad to the online laser, which then makes the right number of holes with the right diameter in the packaging, ensuring optimal gas permeability for the product.

The camera checks all perforations for accuracy, and any deviations are immediately automatically compensated.

The O2-Control ensures that the correct gas composition is maintained at the time of packaging, while the laser perforations and gas permeability of the film keep the gas values constantly at the optimal level, keeping the salad well asleep straight from packaging. In the last fragment of the video it is visible on the gas analyzer that the oxygen level has been reduced to 5,44% O2, and the perforations will ensure that the oxygen remains at that level, so that the product continues to sleep.

By using PerfoTec technology it is possible to more than double the shelf life of fresh products. As a result, the product reaches the consumer in better freshness. This not only offers benefits for the end consumer, but also gives retailers more sales, fewer write-offs and flexibility in their logistics. Additionally, this helps reduce food waste as less food needs to be thrown away due to extended freshness.

About PerfoTec

We specialize in extending the shelf life of fresh products in the vegetable, fruit and flower trade. There is constant stress in this global trade, because the products (during storage and transport) in the trading chain are constantly aging.

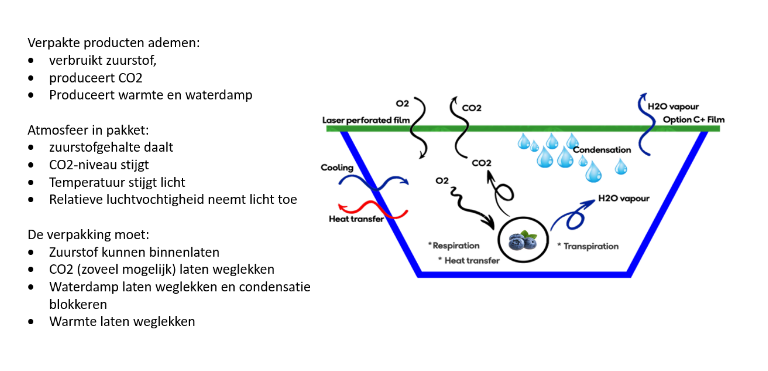

After harvest, vegetables, fruit and flowers continue to breathe and transpire. This causes a potential shortage of oxygen and an increase in carbon dioxide and water in the packaging. The so-called 'respiration rate' of these fresh products is unique for each product.

We extend the shelf life of fresh products by creating the optimal protective atmosphere in the packaging using our unique technology. This protective atmosphere differs per product. This is our important specific know-how.

Schematically it looks like this:

We have systems that allow us to:

- determine the respiration rate of fresh produce;

- perforating the (self-developed) starch foil, the (self-developed) transparent recyclable foil and normal fossil plastic packaging; and

- achieve an optimal protective atmosphere in the packaging

Our technology works on our films, but also on normal fossil plastic packaging. By perforating the packaging with laser microperforations, the aging process after harvest is slowed down for almost all types of vegetables, fruit and cut flowers.

Watch an interview with Bas below Groeneweg.

Our films ensure optimal permeability of oxygen (O2), carbon dioxide (CO2) and water (H2O). In other words: the packaging ensures precise gas exchange with the outside air. We have developed films for the bulk transport market and the retail market. Our compostable or reusable starch film is used for LinerBags for the transport of bulk goods. This film is not always suitable for packaging products intended for the retail market, due to its not completely transparent nature.

We have developed a recyclable transparent film for products for the retail market, together with a chemical group and other partners. Due to its transparent nature, the film is extremely suitable for packaging products for the retail market. This transparent film is easily recyclable and therefore a replacement for current fossil film (made from non-recyclable plastic).

Our films, in combination with PerfoTec's existing technology, significantly slow down the aging process of almost all types of vegetables, fruit and cut flowers after harvest.

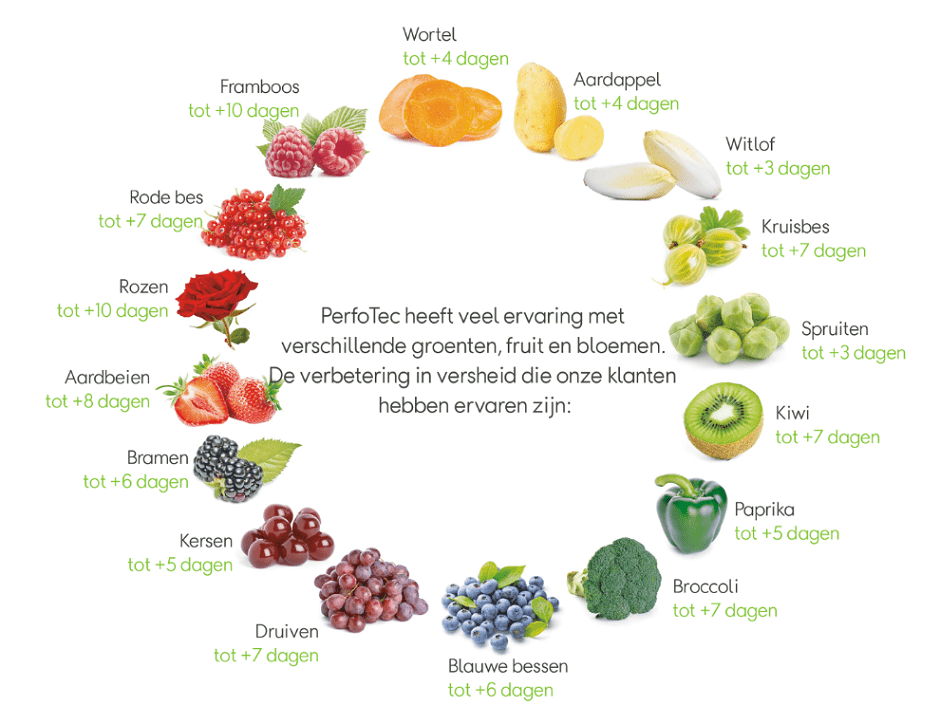

With our systems and techniques and our specific know-how, we offer a total solution to guarantee the best quality for fresh products for the longest possible time. This total solution is unique in the market. We call this the PerfoTec effect. The figure below shows that the products shown have a longer shelf life due to the PerfoTec effect. In combination with the new recyclable transparent film, the products will have an even longer shelf life.

In this time-lapse video you can see the enormous effect of PerfoTec in combination with an earlier prototype of our starch foil.

The table below compares the maximum storage life of certain products between fossil packaging materials and starch foil, which materials are all laser-perforated. It follows that the products have a longer shelf life if the perforated PerfoTec starch film is used.

| Maximum storage life under optimal conditions in days | PerfoTec laser perforation with fossil foil | PerfoTec laser perforation with Stepac nylon Liner Bags | PerfoTec laser perforation with PerfoTec's starch foil Liner Bag |

| asparagus | 12 | 22 | 35 |

| Avocado | 14 | 38 | 65 |

| Paprika | 12 | 17 | 30 |

| Blueberries | 14 | 45 | 65 |

| Broccoli | 14 | 32 | 50 |

| sprouts | 14 | 16 | 35 |

| Celery | 7 | 45 | 72 |

| Cherries | 10 | 25 | 50 |

| Chinese cabbage | 14 | 38 | 65 |

| fresh coriander | 5 | 10 | 15 |

| cucumber | 5 | 11 | 18 |

| dill | 5 | 8 | 15 |

| Aubergine | 5 | 15 | 25 |

| Grapes | 21 | 32 | 65 |

| Green beans | 0 | 12 | 20 |

| peppers | 7 | 12 | 25 |

| iceberg lettuce | 7 | 14 | 35 |

| Price | 7 | 12 | 21 |

| Mango | 0 | 30 | 50 |

| Papaya | 10 | 15 | 25 |

| Pomegranate | 10 | 22 | 40 |

| Strawberries | 5 | 8 | 15 |

| Sweet pointed pepper | 7 | 16 | 25 |

| Bananas | 30 | 35 | 60 |

| Whom | 30 | 50 | 100 |

| Fresh garlic | 21 | 35 | 90 |

| Maximum storage life under optimal conditions in days | Laser perforation with fossil foil | Laser perforation with Stepac nylon Liner Bags | PerfoTec Laser Perforation with PerfoTec's Starch Foil Liner Bag |

| tulips | 14 | 21 | 35 |

| Rozen | 14 | 21 | 35 |

PerfoTec Effect:

Fresh produce traders and their suppliers can use our equipment and techniques to achieve higher turnover and reduce their costs at the same time. A large number of customers, both growers as packers of fruit and vegetables, already work with the PerfoTec system. They can therefore supply better products with a longer shelf life. As a result they have fewer quality claims. This also helps the retailers to reduce product losses to significantly reduce the number of shops. This comes because there is much less producten exceeds the expiration dateen. A very big retailer in the United States is in the process of rolling out the PerfoTec system to reduce retail losses on their strawberries by more than 50% through an extra 8 days of shelf life. This shall annual savingsto deliver of more than $15 million.

Milestones

Over the past 17,5 years we have invested a lot in Research & Development (“R & D“), continuous innovation and patents. There is plenty of room for this € 5 million spent. As a result, we have now built up a major competitive advantage. We have a wide product range for extending the shelf life of vegetables, fruit and flowers. This has enabled us to acquire a unique market position. No other company in the world has PerfoTec's specialist technology and know-how one roof when it comes to packaging fresh produce. Below we provide a brief overview of our investments over the past years:

- 2004-2005

Development of the unique online laser for packaging machines. A 'one fits all' en 'plug and play' system with an intelligent camera system for detection and control of micro-perforations. To develop this system, costs of €750.000 were incurred.

- 2007-2010

Development of the Fast Respiration Meter. The associated algorithm was also developed. This algorithm makes it possible to measure the respiration rate of fresh products. This can then be translated (also using the algorithm) into the required number and size of perforations in the packaging. To develop this system, costs of € 950.000 were incurred.

- 2011-2017

Development of the first generation of transport Liner Bags. A new, compact online laser was also developed. To develop this system, costs of € 900.000 were incurred.

- 2017-2019

Investment in (further) development. This has resulted in the following products:

-

- PerfoTecO2Control

- a new model respirometer 4.0

- a new, advanced 4-head laser system for foil partners

- a new packaging film based on potato starch

- 2020-2021

In recent years we have invested in (further) development. This has resulted in the following products:

-

- a Laser Perforation System at Oerlemans Packaging in connection with the production capacity of LinerBags

- new recyclable films

- demo equipment

Products

In short, especially in recent times 2 jaren have wanother more than €0,5 million invested in R&D. Over thereby are us now all the way ready to to further enter the global market with our extensive product range.

Markt

We are active in the global fruit and vegetable market. This market is characterized by highly fluctuating prices due to supply and demand fluctuations. This market also experiences structural annual growth due to increased consumption. This is due to population growth, the desire to live a healthier life and the increasing need for top quality.

At the same time, fruit and vegetable harvests are becoming increasingly unpredictable due to climate change. This increases the need for our customers to be able to store fruit and vegetables for longer in order to spread sales.

In addition, there is pressure from retailers to reduce food waste and the use of plastic. We offer a solution for this last point with our new compostable film in collaboration with our film partners.

PerfoTec is active in the following markets

- Retail markets for vegetable, fruit and flower packaging

- Transport markets for vegetable, fruit and flower packaging

The retail and transport markets for flower packaging are new markets that we have tapped into. Our current projects are very successful. This is important in PerfoTec's image in these markets. The Dutch market is a significant market in the flower industry. We are literally (geographically) close to the market. As a Dutch side we play a 'home match'. We see a lot of potential in these markets and see them as growth markets.

Partners & Customers

Management

Bas Groeneweg is the founder of PerfoTec and our director.

So he has been involved with us since the moment we were founded. From 1997 he worked as Managing Director at GreenSprout BV. Bas worked at GreenSprout as General Manager until 2003. Bas is also a director of Stichting Administratiekantoor Green Mountain (the sole shareholder of Green Mountain BV).

Andrzej Kopacz joined us on September 5, 2022. He is our Business Development Manager and supports the entire management team. One of his projects is the “boots on the ground" for PerfoTec Inc. Before this, Andrzej worked for more than 10 years operations manager at Jersey Royal where he introduced the PerfoTec technology on several packaging lines there. Andrzej has a Major of Business and Economics in Cracow (Krakowska Akademia Frycza Modrewskiego) and lived in New York for several years as an exchange student.

Martijn de Bruin has been with us since 2005. He started as a Sales Engineer at our company. He has been since 2012 Technical Director with us and a member of the management team. Martijn is responsible for Technology and Innovation (the engineering department). Martijn completed a higher professional education in Mechanical Engineering at Utrecht University of Applied Sciences.

The engineering department is involved in the production of laser, measuring and gassing systems, project management of these systems and technical development.

Interview with PerfoTec CEO, Bas Groeneweg

Watch the short videos below in which Bas Groeneweg, CEO of PerfoTec, explains recent developments and answers a number of questions from investors.

How will PerfoTec achieve accelerated growth?

PerfoTec successful at Fruit Logistica 2023 fair in Berlin

Technological developments PerfoTec

PerfoTec strengthens the organization with professionals

Soft fruit has a longer shelf life and better taste with PerfoTec packaging

Structure

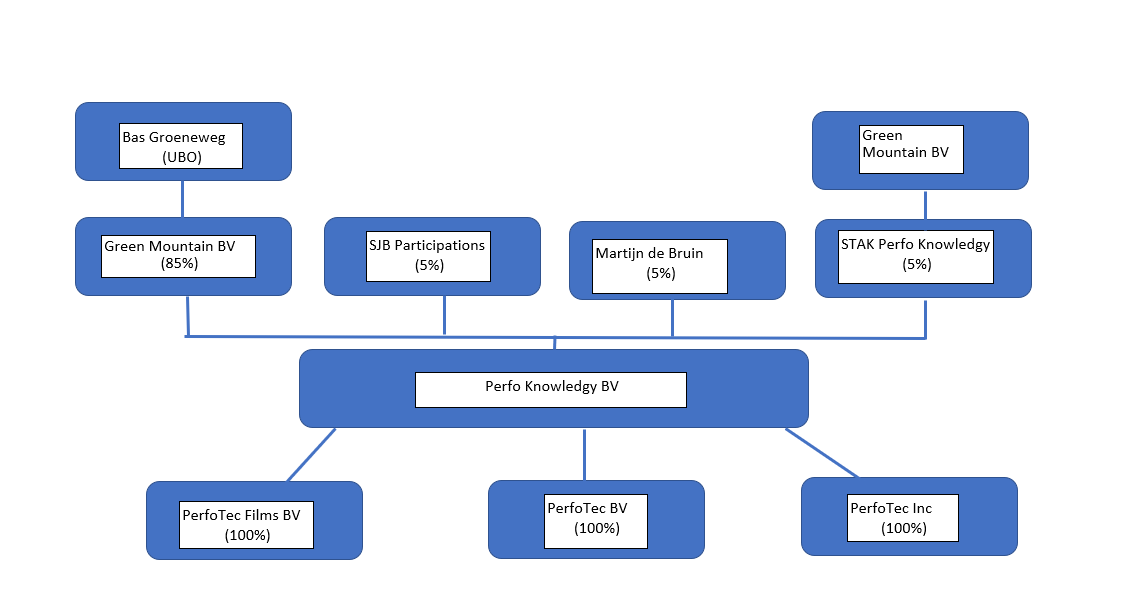

You invest in our company, Perfo Knowledgy BV Our shareholders are Green Mountain BV, SJB Participations, Martijn de Bruin and Stichting Administratiekantoor Perfo Knowledgy. We are part of a group of companies. Below we schematically show our shareholder structure.

Juridic structure

Target emission

Stichting Administratiekantoor Perfo Knowledgy wants to sell € 1.000.005 worth of certificates. We also want to borrow € 1.500.000 from investors. Are all certificates and bonds sold? Then we will receive a maximum of € 2.500.005. We want to use this money for various purposes.

- Expanding our sales market in the United States.

- The better protection of our technology through the application of patents.

- Placing new transparent and recyclable film on the market.

- Installing a Laser Perforation System at a Spanish film processor of retail packaging.

- The investment requirement for purchasing roadrunners to conduct demos in the rest of the world (other than the United States).

- Expanding the PerfoTec team.

- We are also working on the innovation of using the starch film as a recyclable stretch film as a wrapping film for packing bulk goods on pallets.

Bond loan:

| This is what we want to spend the money from the bond loan on, in order of importance: | If we sell €1.500.000, we want to spend it as follows: | If we have €1.000.000 sell, we want to spend it as follows: | If we have €500.000 sell, we want to spend it as follows: |

|---|---|---|---|

| USA roll-out equipment en Setting up USA team | 400.000 | 300.000 | 150.000 |

| Foil patents countries phase | 150.000 | 150.000 | 150.000 |

| Working capital – stock of foil PerfoTec Movie | 200.000 | 110.000 | 100.000 |

| Laser – foil converter Spain | 100.000 | - | - |

| Roll out equipment did not-USES Nations | 210.000 | 140.000 | 50.000 |

| Organizational structure | 290.000 | 200.000 | 50.000 |

| Innovation pallet solution (starch stretch film) | 150.000 | 100.000 | - |

Certificates issuance:

In order to issue the certificates, Stichting Administratiekantoor Perfo Knowledgy will purchase the underlying shares in our capital from Green Mountain BV. With the proceeds from the certificates, Stichting Administratiekantoor Perfo Knowledgy will pay the purchase price for the relevant shares to Green Mountain BV. Green Mountain BV will keep an amount equal to that purchase price (maximum € 1.000.005) available to lend to us as a private loan(s) if we need it.

| This is what we want to spend the money from the current account loan on, in order of importance: | If we borrow € 1.000.005, we want to spend it as follows: |

|---|---|

| USA roll-out equipment en Setting up USA team | 300.005 |

| Foil patents countries phase | 150.000 |

| Working capital – stock of foil PerfoTec Movie | 110.000 |

| Laser – foil converter Spain | - |

| Roll out equipment did not-USES Nations | 140.000 |

| Organizational structure | 200.000 |

| Innovation pallet solution (starch stretch film) | 100.000 |

With the placement of certificates, the capital base of Perfo Knowledgy BV is strengthened now that the purchase price for the shares related to the certificate issue remains available for the capital needs of Perfo Knowledgy BV

Risks and certainties

There are risks associated with share certificates. These share certificates are therefore only suitable for persons who are prepared to take these risks. You can read about the risks in the prospectus. These risks are explained in more detail in the prospectus, as well as the impact that these risks may have on continuity. It is important that you carefully consider these risks and read the prospectus and information document before investing in our depositary receipts.

Investing in bonds always involves risks. The main risk you run is that Perfo Knowledgy BV has no money to repay you or to pay the interest. This could be the case if parties take a lot of time in making decisions about the purchase of our systems or if parties with whom we work do not fulfill their agreements with us. Then you may not receive any repayment of the loan and you will not receive any interest.

No further guarantees are provided. For the complete risk analysis, we refer you to prospectus,/u> and the information document for share certificates and the information document for the bonds.