LCS Piping

LCS Piping

LCS Piping International was formed to acquire LCS Piping. LCS Piping is the specialist in bending materials for, among others, the luxury yacht building industry. LCS Piping has been active in the luxury yacht building industry for 23 years and has specialized in bending and assembling various materials, including steel, stainless steel, cunifer and mapress pipework.

One-time discount on the purchase price

We believe it is important that our investors support this bond issue and this proposition. We would therefore like to offer our investors a one-off discount. We want to give extra reward to investors who buy a substantial amount of bonds.

The amount of the discount depends on the total number of bonds purchased by an investor during the entire subscription period of the issue, including any extensions. This payment will take place at the same time as the first interest payment once the issue is closed. The discount therefore only applies to a successful issuance of bonds and will be paid out to the NPEX account after the closing of the entire issue with the subsequent interest payment.

Note: The full amount, including 1% emission costs, must be paid during registration.

The effective price per bond therefore becomes lower. You can see how this works in the table below:

| Registration amount | One-off discount per bond | Effective price per bond including issuing costs |

|---|---|---|

| €1.000 – €4.000 | None | €1.010 including issue costs |

| €5.000 – €9.000 | 1% (€10 per bond) | €1.000 including issue costs |

| €10.000 – €24.000 | 2% (€20 per bond) | €990 including issue costs |

| €25.000 – €49.000 | 3% (€30 per bond) | €980 including issue costs |

| €50.000 – €99.000 | 4% (€40 per bond) | €970 including issue costs |

| €100.000 – €249.000 | 5% (€50 per bond) | €960 including issue costs |

| €250.000 or more | 6% (€60 per bond) | €950 including issue costs |

LCS Piping International

We are not currently running a business. We were recently founded by our shareholder Gouden Buys BV. We plan to purchase LCS Piping BV and LCS Services BV (hereinafter: “LCS”).

Our goal is to become a dominant player in the market for processing (steel) pipe products. We want to achieve this by growing with LCS and, among other things, by acquiring companies that supplement or support LCS.

We believe that LCS is a well-profitable company with a solid foundation and good growth prospects. LCS has a good positioning within the market. In addition, LCS is the only one in the Netherlands that has a so-called Mapress bending certificate. We believe that LCS's good positioning offers room to expand within this industry. We also think this is a solid basis for expanding into other industries. This may or may not be supported by future acquisitions.

The current owner and director of LCS wants to sell LCS and focus on other matters. We are interested in LCS and therefore want to purchase LCS from the current owner. The seller will remain involved with LCS in an operational role until June 30, 2021. The seller will then focus on other matters within the company, including the development of LCS growth scenarios.

LCS Piping (“LCS”)

LCS Piping is the specialist in bending materials for, among others, the luxury yacht building industry.

LCS was founded in 1997 and has since developed into a specialist in bending steel, stainless steel and cunifer tubes, which are mainly used for the construction of luxury (super) yachts. In addition, LCS also supplies complete pipeline installations for both new construction and repair purposes. The company distinguishes itself from other bending companies because it is the only one in the Netherlands with a Mapress bending certification, which will be explained later. As mentioned, LCS's core activity is the supply of (curved) parts for the yacht building industry, but the company has also expanded into other industries and produces and supplies, among other things, street furniture, bicycle racks, pressurized water tanks and fuel units.

LCS has now developed a strong relationship with its customers and suppliers, is innovative and reliable, which gives it a strong position within the industry.

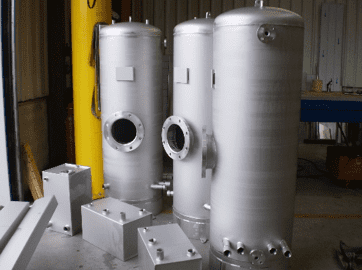

Machinery

Mapress bending

LCS is the only company in the Netherlands that is certified by Lloyd's Register (LRQA) for bending Mapress. Mapress material is thinner material, which is used in combination with couplings. These couplings are very expensive and there is a greater risk of leakage. By bending it, the couplings are no longer necessary, which minimizes the risk of leakage. In addition, there are fewer pinch bends in the pipes and extreme precision is required. Mapress is therefore mainly used in yacht building to save weight. Because LCS is the only one in the Netherlands with a certificate, LCS can respond to the increasing demand for lighter material and further distinguish itself from competitors and the chance of new entrants is also minimal.

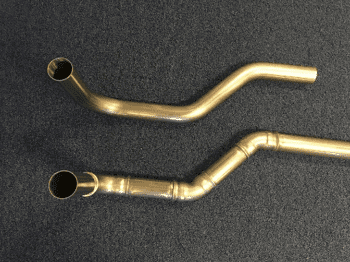

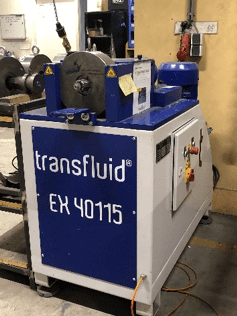

CNC benches & expanding machine

LCS has advanced machinery for the production of LCS's tailor-made products. LCS has 5 CNC-controlled bending benches, making it possible for LCS to bend pipes with a bending radius of 1½D. In addition, LCS also uses various bending tools, which makes it possible for LCS to bend up to 5".

Since 2020, LCS has also been certified by Lloyd's register for expanding pipes in steel, stainless steel and Cunifer. Expanding allows the diameter of a pipe to be increased. A special expanding machine was purchased for this purpose.

Thanks to all this modern equipment, the high quality and experience of the employees, LCS can supply pipes in almost all shapes and sizes, and weld-seamless customization.

Portfolio

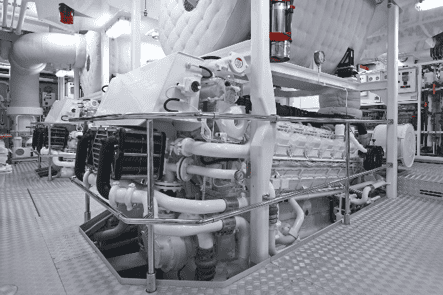

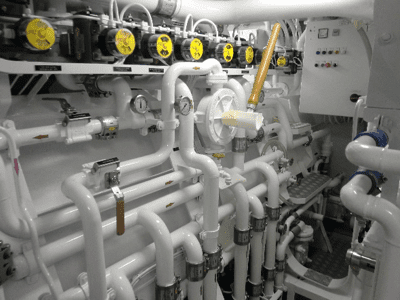

LCS, as mentioned earlier, specializes in bending pipes for, among other things, pipeline installations for the construction of yachts. The assignments are basically the same, but the size, pipe thickness, material, type of bend, etc. distinguish these assignments from each other, meaning that each assignment is tailor-made and therefore each pipe is unique. Of all the yachts shown in the photos on this page, the pipework was supplied by LCS with the exception of the PVC pipes. For the Sea Owl, LCS supplied 2.393 pieces of stainless steel, cunifer and steel pipes. These are used for, among other things, the engine room, air conditioning, dirty and clean water, as well as the water drainage on the deck, the whirlpool, the swimming pool, etc. But this delivery also applies to all other yachts. Below you will find a number of photos of the pipework that LCS supplies and the end products:

Ms. Sea Owl (2013); Royal of Lent Shipyar; construction number 807; length 62 meters

MS Symphony (2015); Royal van Lent Shipyard; building number 808; length 101,5 meters

Ms Lady S (2019); Royal van Lent Shipyard; building number 814; Length 94 meters

Urea tank

LCS also produces and supplies Urea tanks. These tanks have been specially developed for the storage of AdBlue. AdBlue is an aqueous solution used to convert up to 85% of NOx emissions (nitrogen oxides) into water and nitrogen. This significantly reduces air pollution. This product is also supplied and installed by LCS on every yacht.

Helifuels

In addition to supplying piping for yacht building, LCS also supplies street furniture that includes bicycle racks and standards for road signage for recreational areas, for example. LCS also produces and supplies helifuels. These are fuel storage areas for helicopters. An example of this can be seen in the photo:

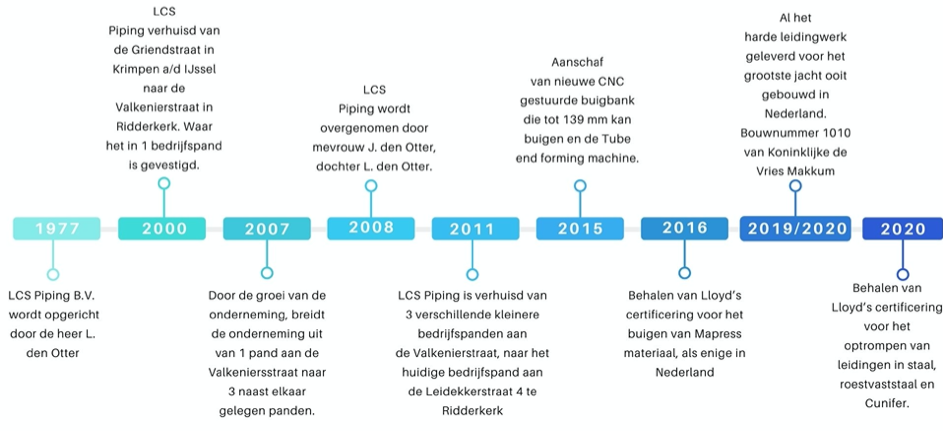

Timeline

Markt

LCS is mainly active in the yacht building industry. Despite the current corona crisis and the decline in the global economy, the demand for luxury (super) yachts is (still) growing. Because LCS customers supply a luxury segment, the economic effects are minimal, allowing projects and orders to continue.

About 25% of all luxury (super) yachts built are produced in the Netherlands, making Dutch yacht builders among the best in the world. Superyacht construction has its own dynamics and is mainly focused on export. There are a total of 18 locations where superyachts longer than 24 meters are built in the Netherlands and this number is growing. Dutch superyacht builders are investing more in new and larger production halls to meet the growing demand for larger and longer luxury superyachts by foreign customers. Despite the growing demand for larger, longer, higher and deeper superyachts, there is a demand that the weight does not increase in the same proportion, which means that increasingly lighter materials are being considered for, among other things, pipeline installations. Mapress bending offers a good solution for this, because, as mentioned earlier, it is lightweight.

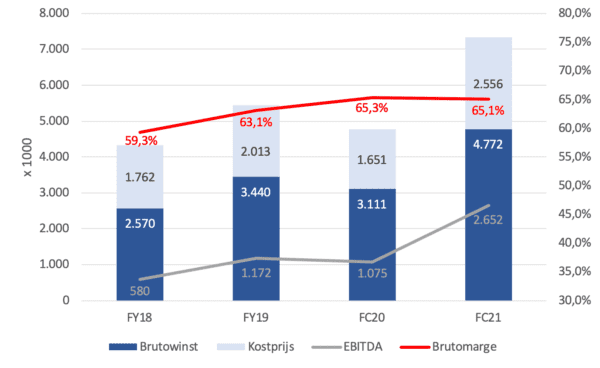

Graph turnover and profit

Customers

Management

Jolanda den Otter

Jolanda den Otter is the current owner & general manager Technical Manager of LCS Piping. She has been the indirect owner of LCS Piping since 2008. She is also the daughter of the founder and former owner of LCS Piping. Before she became the owner of the company, she already worked as an administrative assistant and, through her father's work, has a lot of experience in regular shipbuilding and luxury yacht building. Jolanda den Otter will remain involved with LCS in an operational role at least until June 30, 2021. Jos Louwhoff will then take over her position within the company. Jolanda den Otter will then focus on other matters within the company, including the development of LCS growth scenarios. She will also remain involved in the company as an investor through this bond loan as previously explained in this prospectus.

Ton Goossens

I would like to introduce myself to you. My name is Ton Goossens and I have been a director of LCS Piping International bv since May 6, 2021.

I have been active as an independent business advisor since 2005 and in that capacity I became involved in the purchase/sale of (LCS) Piping bv.

After the director resigned, the shareholder asked me if I wanted to become a director. I see it as my job to manage the contract with NPEX and to direct it in accordance with agreements with NPEX and the Bondholder Interest Foundation. I am in consultation with the chairman of the aforementioned foundation and see the collaboration as positive and professional.

Nico Leeuwenburg

Nico Leeuwenburg is the current technical manager of LCS Piping. Nico Leeuwenberg has been involved with the company since the founding of LCS Piping in 1997. He had previously been employed by the founder of LCS Piping since 1993. Nico Leeuwenburg has a lot of experience in the yacht building industry, partly because his father also works in this sector.

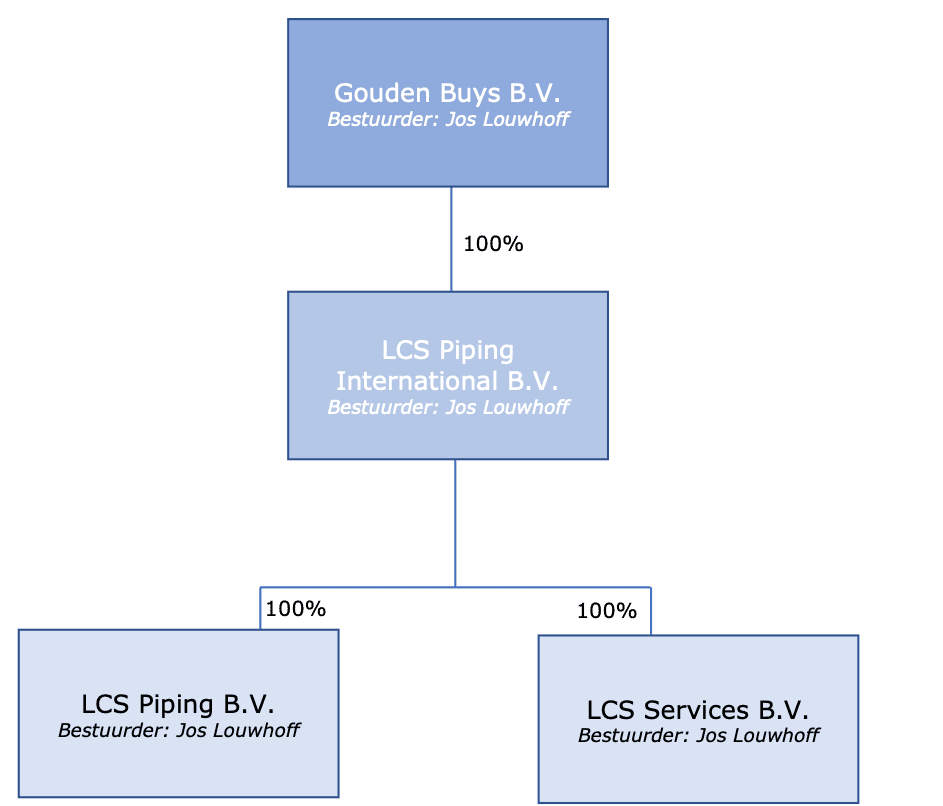

Structure

The structure of the company after the acquisition is as follows:

Main risks

Investing always involves risks. The main risk you run is that LCS Piping International will not have the money to repay you or pay the interest. This could happen, among other things, if customers do not return and we do not grow sufficiently. Then you may not receive any repayment of the loan and you will not receive any interest.

No further guarantees are provided. For the complete risk analysis, please refer to the prospectus and the information document.

Rates

The rates charged by NPEX are shown below.

| NPEX account | free |

|---|---|

| Deposit money | free |

| Registration fee for issue | 1% one-off |

| Service fee | 0,05% per month* |

*To be calculated based on the nominal value of the bonds in the portfolio on the coupon payment date and to be offset against the (monthly) interest payment.